Concrete finishing is an essential step in any construction or renovation project. To achieve optimal results, professionals must choose the right concrete finishing tools. Ergonomics, performance, and profitability are among the factors to consider when making an informed decision about your tool selection. Discover the criteria for selecting the best concrete finishing accessories.

The Economic Factor

The economic factor is one of the most important criteria to consider before purchasing equipment, especially concrete finishing tools. This element can have a direct impact on a professional’s operational profitability.

Total Cost of Ownership

The total cost of ownership, or TCO (which impacts the return on investment, or ROI, in the long term), represents all costs associated with a product or equipment throughout its lifespan. This indicator encompasses both direct costs attached to a tool and expenses incurred during its use. Thus, the total cost of ownership includes all expenses related to the acquisition, use, and disposal of an asset throughout its lifecycle.

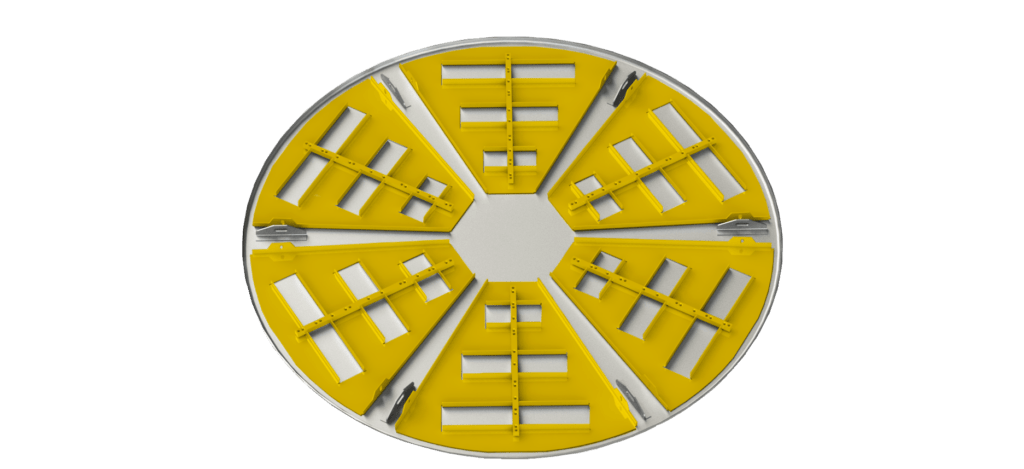

To compare the total cost of ownership between two products, the example of the Big Foot Float Pans saver system from Plate2000 is interesting. This device is installed on a ride-on trowel and reduces disc wear used on machines intended for smoothing and finishing concrete on large work surfaces. Compared to conventional systems, this equipment may have a higher initial cost. Still, its ability to extend disc life and reduce replacement frequency leads to reduced maintenance costs and work interruptions. When considering the ROI for a Big Foot Float Pans saver system, a professional can thus achieve significant savings in the long term while maintaining optimal quality in completing their concrete finishing projects.

Impact on Productivity

The interest in investing in a specific tool for concrete finishing can also be justified by the impact its use generates on productivity. The case of a 3D scanner can illustrate the importance of this criterion before a purchase. Using this device to inspect concrete slab flatness offers considerable advantages in terms of productivity compared to traditional methods. A 3D scanner can scan a surface in minutes, whereas manual verification would take several hours or even days for large surfaces. This speed allows for significantly accelerated quality control processes. These devices also offer measurement precision far superior to manual measuring tools. They can detect the most subtle defects, such as slight undulations or unevenness, which might go unnoticed during visual inspection.

These advantages help financially justify the investment in new equipment. The return on investment is demonstrated by quantifying time savings, reduced labour costs, and improved finishing quality.

Technical Factors and Performance

The choice of a concrete finishing tool is wider than considering only the economic factor. Other elements, such as technical characteristics and performance, should also attract your attention before selecting the best equipment. The finish quality can depend largely on the technical characteristics of the tool used.

Tool Suitability for Your Project Types

The choice of concrete finishing tools is a determining factor for project success. The tool’s adaptability to the task being performed is crucial. Thus, one must consider the versatility of specific tools capable of adapting to different finishes or projects. A vibrating screed, for example, can be used to smooth large surfaces or create finer textures. More specialized tools may be more appropriate for concrete finishes, such as polished concrete or exposed aggregate concrete. It’s also important to consider the size of the worksite. A manual tool may be sufficient for small jobs, while a ride-on trowel equipped with the Big Foot Float Pans saver system is more suitable for large surfaces. The tool is, therefore, chosen according to project specifications, favoring the optimal combination between versatility and specialization to guarantee quality results within the allocated timeframe.

Durability and Reliability

Durable equipment, capable of withstanding wear and harsh working conditions on a construction site, guarantees a long tool life and reduced replacement and maintenance costs. Concrete finishing work often takes place in demanding environments. Devices and tools may be exposed to abrasive materials, moisture, or extreme temperatures. Choosing a tool designed to withstand these conditions is crucial.

For a professional, one of the objectives is to minimize the frequency of breakdowns and downtime related to equipment maintenance. With this in mind, purchasing reliable equipment avoids costly interruptions and construction delays. By prioritizing reliable tools designed to last, construction professionals ensure optimal return on investment and consistent work quality.

Various Factors: From Ergonomics to After-Sales Service and Energy Efficiency

Professionals can also consider many other additional criteria to guarantee an interesting, profitable, and sustainable investment. The tool’s ergonomics is thus a crucial characteristic, ensuring user comfort and safety. Environmental footprint is also becoming an increasingly important criterion today, with professionals preferring environmentally friendly equipment with low emissions. The tool’s energy efficiency can also be decisive: it allows for selecting tools based on their environmental impact.

Another criterion is the after-sales service offered by the manufacturer. Its availability and responsiveness ensure quick maintenance and repair of tools in case of breakdown, thus limiting work interruptions. The manufacturer’s reputation is another key indicator of the device’s reliability and quality, as it demonstrates the supplier’s expertise and commitment to offering durable and high-performing products.

Conclusion

For concrete finishing professionals, choosing the right tool to use on construction sites is an important decision that directly impacts work quality and productivity. Beyond its characteristics, professional equipment can be selected based on multiple factors, from financial cost to ergonomics, not forgetting durability, performance, and maintenance options. How do you find the best tool for concrete finishing? The essential thing is to analyze your needs carefully and then rank the most important criteria for your company. Thus, you will succeed in choosing the tool best suited to your projects.